AI Breaks Log Jam for the Aerospike Thruster

Beyond the Headlines: From Vision to Value

For decades, NASA and aerospace engineers worldwide pursued a dream: build a rocket engine that could maintain high efficiency across all altitudes, from ground level to the vacuum of space. This elusive design, the aerospike thruster, held the promise of revolutionizing space travel. Unlike traditional bell-shaped nozzles that optimize for specific atmospheric conditions, the aerospike thruster uses its unique spike design to adjust to changing atmospheric pressures. This capability could enable single-stage-to-orbit (SSTO) spacecraft—rockets that need no multi-staging or complex separation mechanisms, greatly simplifying launches and cutting costs.

Yet, despite its theoretical brilliance, the aerospike has remained largely unrealized. The obstacles seemed insurmountable:

Cooling Challenges: The spike is surrounded by exhaust gases reaching temperatures above 5,000°F. Developing cooling systems capable of handling these extremes was a technical bottleneck.

Manufacturing Complexities: Traditional methods couldn’t fabricate the intricate internal channels and geometries required for an effective aerospike design.

Iterative Costs and Timelines: Testing and refining designs was time-consuming and expensive.

NASA and others tried without success. The XRS-2200 linear aerospike, designed for the X-33 spaceplane in the 1990s, came close but was canceled due to technical and budgetary constraints. The dream dimmed further as the industry shifted focus to tried-and-tested technologies like SpaceX’s Falcon rockets.

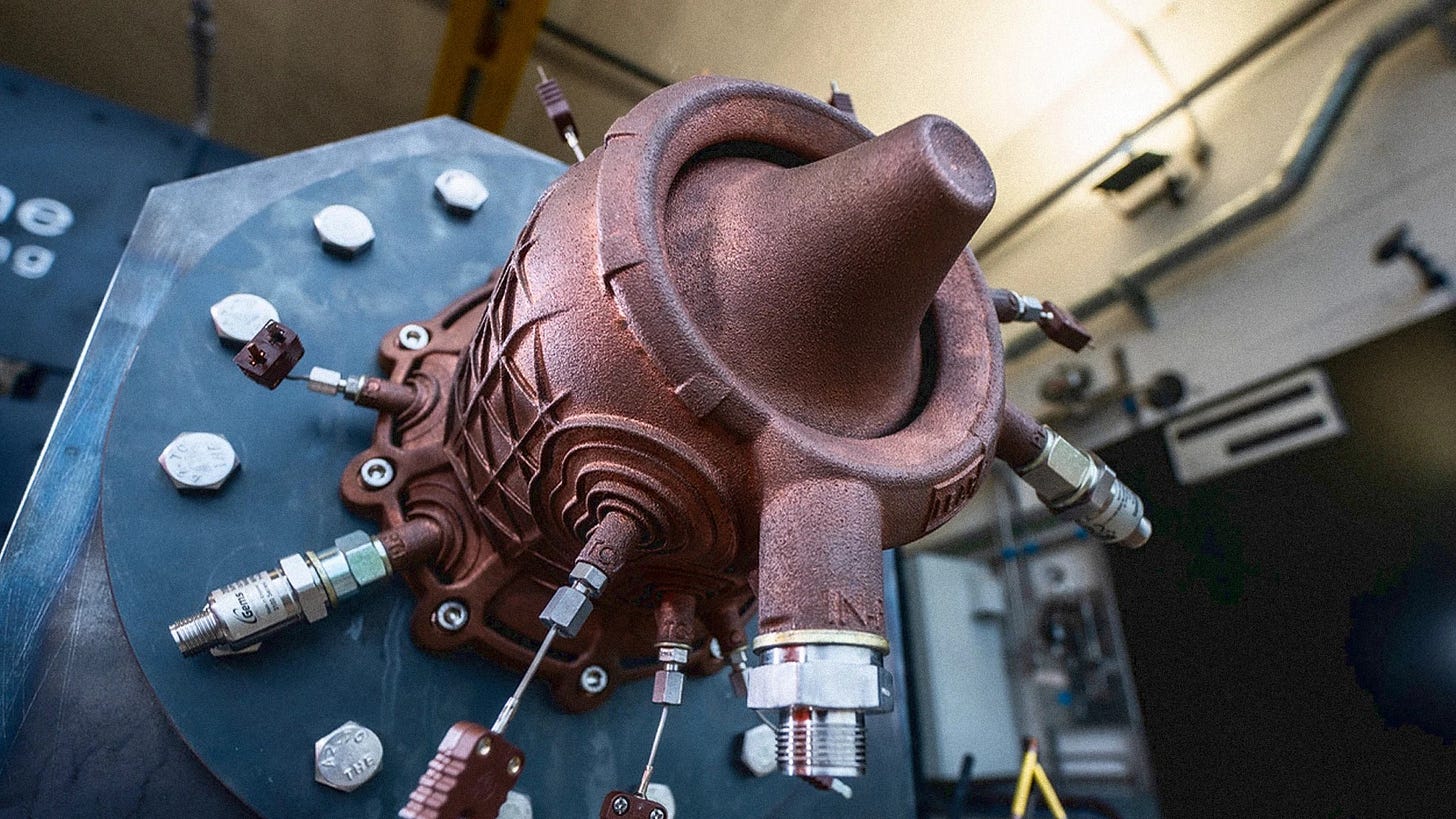

Enter AI. A two-person startup, Leap71, set out to reimagine aerospace engineering with the help of their AI platform, Noyron. Their goal was audacious: use AI to design an operational aerospike thruster in weeks, not decades. Noyron combined data from earlier engine projects with physics-based simulations, autonomously generating a design that overcame the historic hurdles:

Cryogenic oxygen and kerosene cooling channels were intricately integrated.

The design was optimized for 3D printing using advanced alloys.

Testing iterations were condensed from months to hours, as Noyron adapted and refined based on real-world feedback.

In December 2024, the aerospike thruster was successfully test-fired on its first attempt—an historic moment made possible by the AI-led revolution in design and engineering.

Defining the Need

Root Problem:

Traditional rocket engines are inefficient across varying atmospheric conditions, requiring multi-stage designs that increase costs, complexity, and risks. Despite its theoretical advantages, the aerospike thruster—a single-stage-to-orbit engine—remains unrealized due to challenges in cooling, material strength, and manufacturability. This stagnation impedes innovation in cost-effective and sustainable space exploration.

Symptoms:

Rockets require multiple stages, increasing operational costs and reducing reusability.

Existing aerospike designs have failed due to material degradation under extreme temperatures.

Iterative testing for complex designs is prohibitively slow and expensive.

Underlying Issues:

Engineering Complexity: Designing efficient cooling mechanisms for high-temperature spikes.

Manufacturing Limitations: Traditional methods can’t create intricate geometries for cooling channels.

Process Inefficiencies: Prolonged timelines for iterative design and testing hinder innovation.

This Thruster has Answers:

The cryogenic aerospike thruster addresses these issues by a) simplifying rocket design and reducing cost barriers, (b) maintaining thrust performance across all altitudes, (c) reducing resource use and waste in rocket development, and (d) leveraging AI to accelerate innovation, adapt to challenges, and democratize advanced engineering for startups and smaller players.

This problem statement sets the stage for exploring the societal and business benefits of AI-driven engineering while also emphasizing the broader implications for innovation and accessibility in space exploration.

How AI Resolved the Problem

AI was central to the rapid and groundbreaking development of the cryogenic aerospike thruster. By integrating advanced computational techniques, AI not only addressed historical engineering challenges, but also fundamentally transformed the design and testing process. The key aspects of AI's contributions were:

1. Accelerated Design Process

Traditional engineering methods required extensive manual calculations, prototyping, and iterative testing, often spanning years. AI revolutionized this process by:

Automated Design Generation: Leap71’s AI platform, Noyron, autonomously created designs optimized for performance and ability to manufacture. It produced CAD files ready for 3D printing within minutes, eliminating much of the trial-and-error inherent in traditional workflows.

Physics-Based Simulations: AI integrated physics models to predict engine performance, thermal stress, and fluid dynamics, ensuring that designs met rigorous technical requirements before physical testing began.

2. Optimization of Cooling Systems

One of the most significant challenges in aerospike development was managing extreme temperatures around the spike, which sits amidst exhaust gases exceeding 5,000°F. AI addressed this by:

Designing Complex Cooling Channels: Using advanced algorithms, AI developed intricate cooling channels for the spike and combustion chamber. These channels were optimized for cryogenic oxygen and kerosene flow, balancing cooling efficiency and structural integrity.

Thermal Analysis and Feedback: AI analyzed test data in real time, updating thermal models to improve the design and reduce the risk of overheating or structural failure.

3. Innovative Manufacturing Techniques

AI played a pivotal role in adapting the aerospike design for modern manufacturing methods:

3D Printing Compatibility: Noyron generated designs tailored for laser powder bed fusion, a cutting-edge 3D printing technique. This allowed for the creation of complex, monolithic structures that traditional manufacturing could not achieve.

Material Selection: AI algorithms evaluated and recommended material compositions, such as copper alloys with chromium and zirconium, that balanced thermal conductivity, strength, and resistance to high temperatures.

4. Data-Driven Iterative Testing

AI significantly reduced the time and cost of testing by:

Real-Time Test Data Analysis: During hot fire tests, AI analyzed data on combustion efficiency, cooling effectiveness, and structural performance. These insights informed immediate design refinements.

Rapid Iteration: Unlike traditional engineering cycles that required months between tests, AI-enabled systems could integrate new data into updated designs almost instantaneously, allowing for quicker convergence on optimal solutions.

5. Overcoming Historical Barriers

AI circumvented many challenges that had hindered aerospike development in the past:

Complex Geometries: The intricate shapes required for optimal aerospike performance could previously not be manufactured. AI’s ability to work seamlessly with 3D printing unlocked these possibilities.

Cost Reduction: By automating design and minimizing physical prototypes, AI significantly cut development costs, making high-risk projects like the aerospike more feasible.

Risk Mitigation: AI simulations reduced the need for "blind testing" by predicting potential failure points and optimizing designs beforehand.

6. Scalability and Future Applications

AI not only helped develop the aerospike thruster, but also set the stage for future advancements:

Continuous Learning: Noyron’s ability to incorporate test results into its algorithms means that every test improves the system’s understanding, leading to progressively better designs.

Adaptability: The same AI-driven methodologies can be applied to other complex aerospace challenges, such as hypersonic flight systems, reusable rockets, and interplanetary propulsion.

7. Enabling Collaboration and Knowledge Sharing

AI also facilitated communication and collaboration among stakeholders:

Unified Design Language: AI-generated models and simulations provided a common framework for engineers, manufacturers, and researchers to collaborate.

Democratizing Aerospace Innovation: By reducing the technical and financial barriers to advanced propulsion design, AI allowed smaller companies and startups to compete with established aerospace giants.

Stakeholders in Aerospike Thruster Development

Developing and implementing a cryogenic aerospike thruster involves diverse stakeholders with varying interests, expertise, and responsibilities. Here is a categorized list of stakeholders and suggested strategies to effectively engage them:

1. Government and Public Sector

NASA: As the primary space exploration agency, NASA plays a central role in funding, oversight, and providing technical expertise.

Regulatory Agencies: FAA, FCC, and international bodies that oversee spaceflight safety and communication.

Engagement Strategies:

Align project goals with NASA’s strategic interests (e.g., single-stage-to-orbit, cost-effective launches).

Maintain transparent reporting on technical progress, safety standards, and mission alignment.

Collaborate on research initiatives and share data to foster innovation within NASA programs.

2. Industry Partners

Aerospace Companies: Collaborators like SpaceX, Boeing, and Lockheed Martin may offer testing facilities, resources, and design insights.

Material and Manufacturing Specialists: Providers of advanced alloys, 3D printing services, and heat treatment technologies (e.g., Aconity3D, Fraunhofer Institute).

Startup Innovators: Companies like Leap71, which spearheaded AI integration into aerospike design.

Engagement Strategies:

Establish formal partnerships to leverage expertise and infrastructure.

Share development risks through joint ventures or funding agreements.

Host workshops and knowledge-sharing sessions to integrate cutting-edge industry practices.

3. Academic and Research Institutions

Universities (e.g., University of Sheffield, MIT): Provide research capabilities, graduate talent, and collaboration in testing phases.

Specialized Research Centers: Experts in propulsion, materials science, or AI-driven engineering.

Engagement Strategies:

Offer internships and research grants to involve students and faculty.

Organize academic conferences and publish findings in peer-reviewed journals.

Use university labs for prototype testing and validation.

4. International and Space Exploration Community

International Space Agencies: ESA, JAXA, and others pursuing collaborative exploration missions.

Global Space Councils: Bodies like the UN Office for Outer Space Affairs (UNOOSA).

Engagement Strategies:

Build frameworks for international collaboration to share costs and expertise.

Address global challenges, such as space sustainability and climate monitoring, as part of project objectives.

Engage in diplomatic channels to align international standards.

5. Private Investors and Funding Bodies

Venture capital firms, angel investors, and government-funded initiatives like DARPA or SBIR programs.

Engagement Strategies:

Develop a robust business case emphasizing cost reduction, increased efficiency, and market potential.

Highlight milestones to demonstrate technical feasibility and reduce investor risk.

Engage in frequent investor updates with clear metrics for progress and ROI.

6. Broader Public and Advocacy Groups

Space Enthusiasts and Citizen Scientists: Build public interest and excitement.

Environmental Advocates: Ensure sustainability in manufacturing and operations.

Engagement Strategies:

Conduct public outreach through media campaigns, webinars, and exhibits at museums or science centers.

Address concerns about environmental impact by demonstrating eco-friendly practices.

Create an educational platform for citizen scientists to engage with data or simulations.

7. Internal Project Teams

Engineers, AI developers, project managers, and quality assurance teams within NASA or partner organizations.

Engagement Strategies:

Implement robust communication channels to ensure clarity in roles and objectives.

Foster a collaborative culture by celebrating milestones and recognizing contributions.

Provide training on new tools and technologies like AI-driven design systems.

8. Media and Public Relations

Science Communicators and Journalists: Translate technical achievements into public-friendly narratives.

Engagement Strategies:

Develop non-technical stories emphasizing the societal benefits of the aerospike thruster.

Use visual aids like animations or infographics to simplify complex concepts.

Engage with science media to highlight progress and inspire the next generation of engineers.

By tailoring engagement strategies to each stakeholder group, the project can foster collaboration, mitigate risks, and ensure the successful implementation of the cryogenic aerospike thruster.

CONCLUSION

AI was not just a tool but a transformative force in the development of the cryogenic aerospike thruster. By combining computational intelligence with innovative manufacturing techniques, it overcame decades-old challenges, accelerating progress in aerospace engineering and setting a precedent for AI's role in high-stakes, cutting-edge innovation. This success story illustrates AI's potential to revolutionize industries, making the impossible achievable in record time.